7 Day Anagama Firing with Peter

Callas

March 30 thru April 12, 2000

At Dan Finchs' Pottery in Bailey, North

Carolina

In America an Anagama is usually loaded with

glazed functional ware and fired over a period of three to four days.

Using Callas technique, unglazed green ware is best suited to benefit

from ash deposit and build-up accumulated during an extended 7 day

firing process. The cooling down period is extended as well to create

a rustic -not glass/glaze-like- surface.

A combination of hard and soft wood will be

used (approx.12 cords). Workshop participants will assist Peter

Callas and his crew in stoking around the clock. The desired

temperature is 2300-2400 degree F (Cone 9-12). The firing is preceded

by 2 days of loading the huge 600cu feet kiln. Peter Callas is a

Master in the technique of tumble stacking a way of placing pottery

in the kiln that maximizes/equalizes heat distribution, ash deposit

and the intriguing art of "painting with fire".

|

Thursday

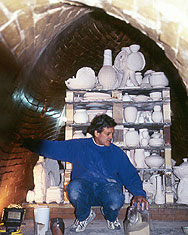

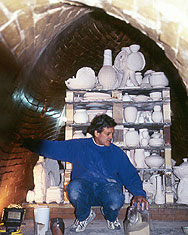

morning: Kiln loading

starts

Tumble stacking starts at

the narrow end of the kiln close to the chimney. (Note: site

ports will be used to stoke with kindling style wood, to

built up ashes and raise the temperature in the back of the

kiln)

|

|

Sets of shelving were placed between

the 3 sets of site stoke ports to hold smaller pieces and

all of the glazed ware.

|

|

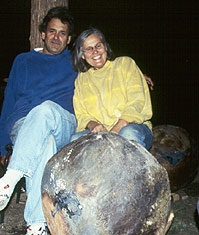

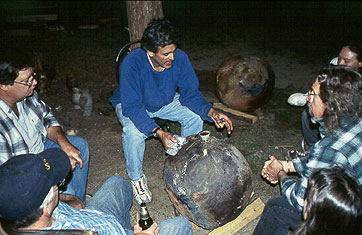

My orbs (approx. 65cm/25

1/2inch diam.) are placed under the front site

ports.

|

|

After 3-4 days of firing they will be

totally submerged in deep bed of amber/ashes.

Friday 2

am.: there is still a lot of

ware to be loaded.

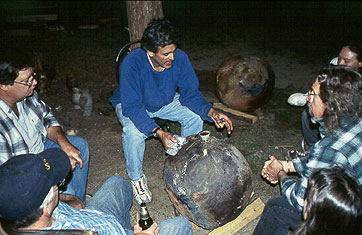

Saturday after

midnight: Peter is

contemplating the placement of a piece of pottery in the

fire box.

|

Saturday 4

am: Kiln loading is finished

The kiln door will be closed and a gas burner will be used

to raise the temperature inside the kiln to about 160

F.

|

|

Goal:

Hold this temperature until kiln and ware are completely

dried out.

|

Saturday/Sunday:

The door is bricked in and the

building of the external combustion platform is completed.

Kindling with pine wood starts. To avoid thermal shock the

temperature will be raised slowly (approx. 30F/hr). This

outside combustion firing will continue for 2 days with the

temperature holding at approx. 800F.

Goal: to

build a bed of coal inside the kiln before fire box firing

starts and to have gas carry fly-ashes throughout the

kiln.

|

|

Monday

morning: Fire-box firing

starts

Goal: to

have the temperature rise 30 to 50 degrees per

hour.

Tuesday 9

pm. 1550F: side-stoking

starts

Temperature difference between back

and front inside the kiln is 250 F.

Goal:

Use side stoking to bring up the temperature in the back and

to have a bed of coal build up throughout the entire kiln

while stoking maintain a +/- 40 degree swing in

temperature.

|

|

Wednesday

midnight: Temperature is at

Cone 6 (2194 degrees F)

Thursday

afternoon: Temperature is at

Cone 11 (2361 degrees F) The temperature in the fire box is

200 degrees higher than in the back of the kiln.

Goal: to

hold the temperature in front while raising the temperature

in the back through more aggressive site stoking. At 9 pm

Cone 12 is bending and the temperature difference front/back

is reduced to 90 degrees.

Friday 1

am: firing down starts

Goal:

Rake amber in firing box gently to burn down coal and create

a protection blanket by covering the pieces in the firing

box first with small then with larger chunks of wood until

the entire box is filled - ending with a blanket of small

pieces. Stoke all site ports using kindling style oak to

fill kiln chambers up as high as possible. Seal the entire

kiln including chimney and damper. At 3:30 am the kiln is

sealed and the front/back temperature difference is 30

degrees.

Friday 4

am: Firing cycle is completed

The front/back temperature difference is 3

degrees.

|

|

|

Kiln Opening: Tuesday

pm.

|

|

|

|

|

|

|

|

|

Back

to Index page